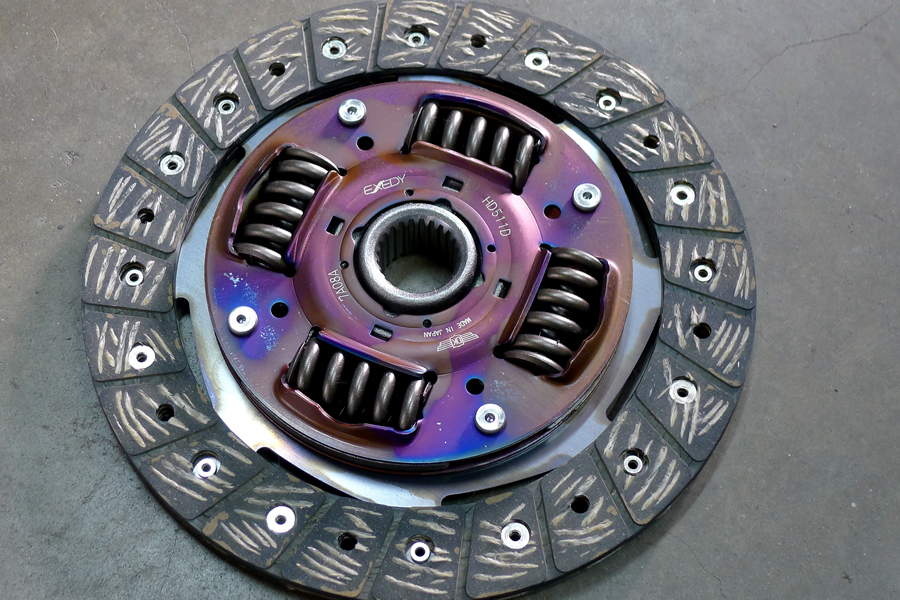

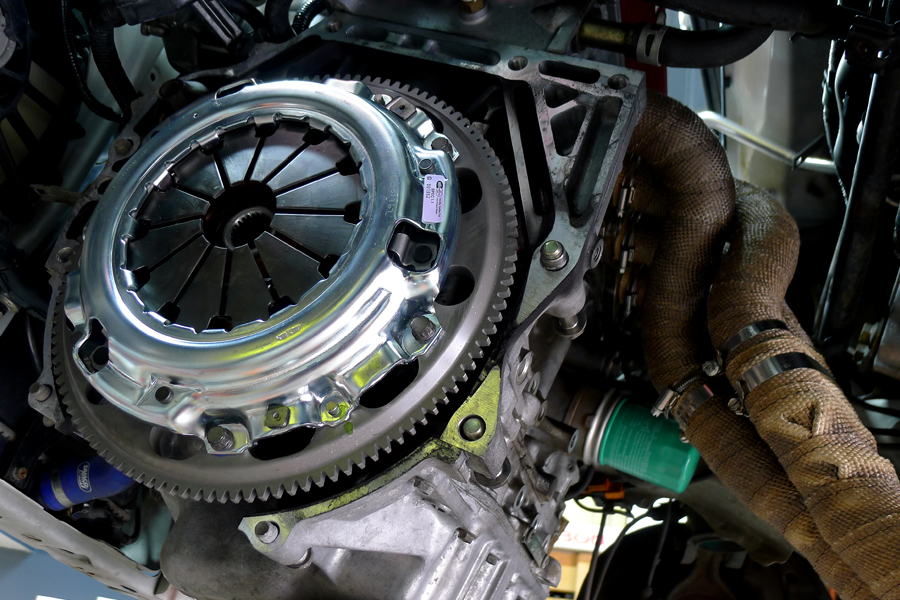

The day has finally come where I part ways with the Exedy Stage 2 clutch. Ideal for every day track use and NOT every day use! The combination of the insane weight and how it is either fully engaged or disengaged made it easy to say goodbye. An Exedy Stage 1 and flywheel would be used this time around. A Stage 1 would be good enough for the two to three times that I would track a year, in return I gain 362 days of driving enjoyment. With the transmission separated, old clutch and flywheel out, it is always a good idea to replace the clutch fork and pivot ball. Looking forward to driving again.

Notes:

EXEDY organic racing clutches only use premium friction materials that are resistant to slippage and burst. Increased clamp loads give the necessary capacity to handle modified engines. This is the preferred clutch for street and light horsepower track use. Driveability is similar to the stock clutch. Pedal efforts will be slightly higher because of the higher clamp loads. All of our clutch discs have spring center dampers to reduce drivetrain shock.

EXEDY Racing Flywheels are made from solid one piece billet chromoly steel forgings. They are specifically designed to reduce weight and inertia for better engine response.

Most incorporate special design features to enhance air flow to improve the cooling of the clutch. The ring gear teeth are milled onto the flywheel unlike an aluminum flywheel where the ring gear is pressed onto the flywheel and have the possibility of separating from the flywheel.